I don’t know what possessed my parents to learn to fly, especially as they did so on tricky, French, WWI aircraft. My father later gave my Mother an aircraft she flew in competitions where her meticulous planning helped her to win trophies. To go on holidays we flew from Brno to the Lido in three engined Fokkers or Savoia Marketis, canvas covered wooden aircraft, unpressurised of course, flying low over the Alps.

I was familiar with aircraft as I was with cars and going very fast forward, when we arrived in the UK, in 1942, I was happy to study aircraft engineering. I enjoyed my three years at Loughborough but I explain elsewhere how my career in the aircraft industry was little short of disastrous.

That changed at Ogle

We got a job from SAAB to build a cabin section for them. When Crossair orderd the new SAAB 2000 model I managed to get the job of introducing some extra flair into their cabins.

Headed by Maurice Suter, this remarkable company specialised in flying passengers from Basel to destinations across the Alps a journey that took trains, buses and cars massively more time.

This was around 1990. At the same time BAe had decided to stretch their feeder liner Jetstream J31 into the 29 seat J41. They needed to show the aircraft at the Le Bourget air show but it wasn’t ready to be flown there. My great luck was that a wonderful man, Nigel Wemyss, who had held senior positions in aircraft industry, was helping me with the management at Ogle and we were able to win the job of designing the cabin and building a full size, fully detailed mock up.

I softened all the shapes and lightened all the colours compared to the J31, brought elements of the exterior logo to the inside. I redesigned the seats, had the J41 embroidered in the headrest and went to Switzerland to have a special fabric woven for them. The challenge of building the mock up was huge as the timescale was short. The fuselage was in aluminium with GRP nose and tail. The cabin was air-conditioned and the cockpit fully detailed. A special touch was the steps to enter the aircraft: I provided a canopy to protect visitors from the usual heat and occasional rain. Our model shop made a quite exceptional effort to get our lovely mock up to the show. ‘Why couldn’t we have a cabin like that’ was the comment from a Dornier representative (who had a nicer aircraft).

And there was another outcome

Airbus came knocking on my door (it was flattering for them to take the initiative, as Renault did also). Bob Lange, the Marketing Director, responsible for the cabin of what became the A380 super jumbo, invited me to Toulouse to comment on the interior.

I consider this as one of my failures: I found the engineers loathe to move out of their comfort zone and I was unable to persuade them to accept ideas that would have made the aircraft a distinct improvement on the Boeing 747 rival.

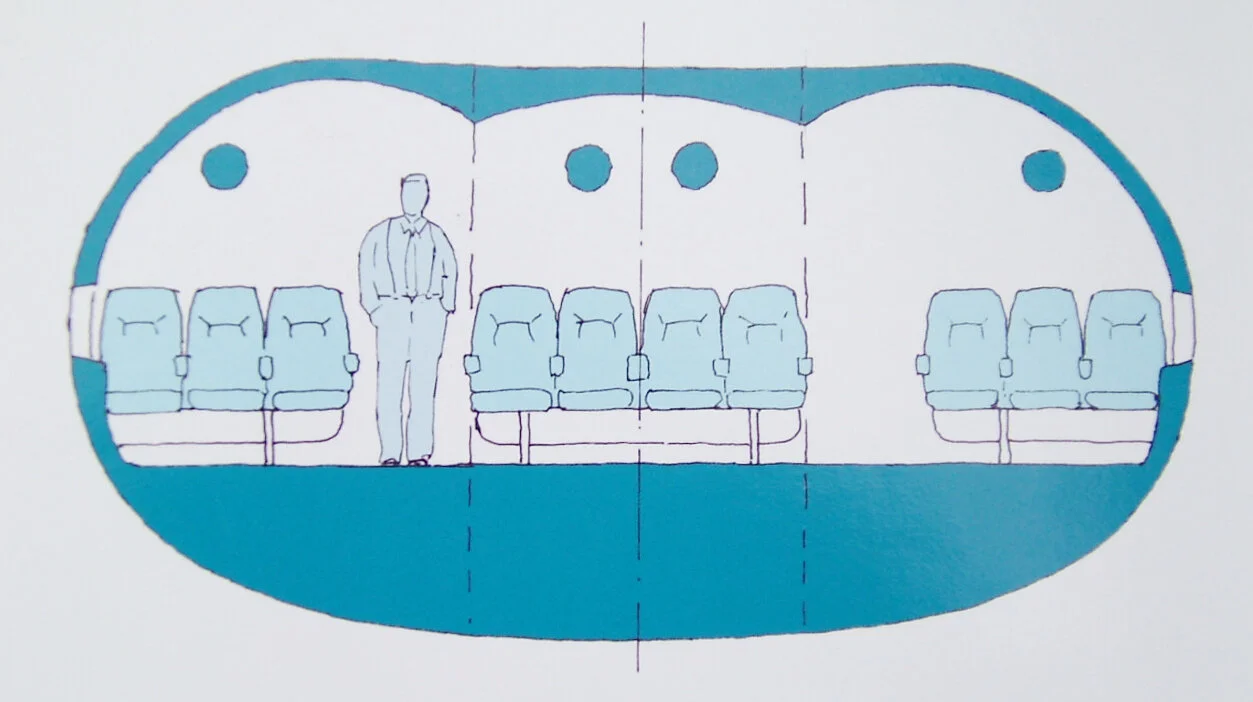

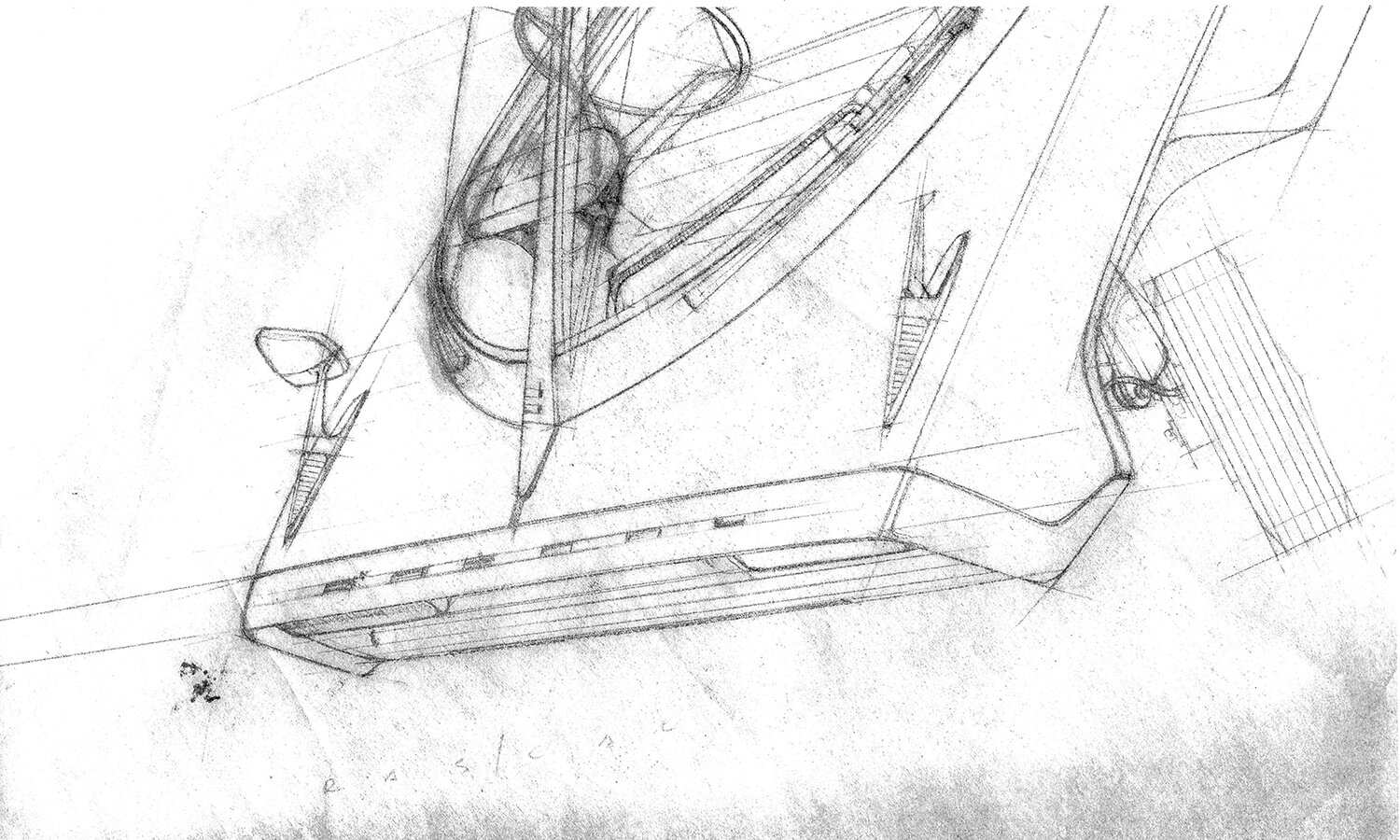

An interesting discovery I made while working for Airbus was that they had toyed with fuselage section spread horizontally, made up of two intersecting ‘bubbles’. I had a rather wild model made with that configuration and a canard wing arrangement. We called it Aircruiser I. Coming down to earth I considered that the most widely used passenger aircraft was the Boeing 737 and Airbus 320 carrying nearly 200 passengers. There was a need for a new generation of such aircraft for 300 passengers and led me to scheme Aircruiser II. It featured again a flat fuselage producing lift but with three horizontal bubbles. Compared to a circular fuselage, where the space under the cabin floor and above the ceiling are underused, this configuration provides room for a much more flexible and appealing cabin.

Aircruiser II would have a welcoming entrance leading to a coffee bar where passengers could get refreshment, stretch their legs and socialise. Luggage would be accommodated in accessible floor to ceiling racks (avoiding the loss of luggage). Locating these randomly would offer the possibility of creating smaller, cosier cabins, even seating around tables for families and groups of friends. To replace the usual bus-like cabins. Separate internet stations would be available. A highly desirable amenity would be purpose designed ladies and gents toilets. There is good evidence that these would be no heavier or expensive than the usual cramped, unisex ones. For the wide, shark like nose I locate the cockpit to one side so that some passengers would have a view forward.

With the flat fuselage providing lift the wings can be smaller and lighter. I also propose a ‘box wing’ configuration, rather like a staggered biplane, that has a reduced span and is structurally efficient. I schemed Aircruise II around the turn of the century and expected something like it to take off within twenty years. Flat fuselages and box wings are being explored by research organisations but there is no evidence yet from the conventional by the leading plane maker.

We worked for the German seat maker Recaro who made seating for major airlines. Apart from their efficiency, I noted that an engineer was running the company. I never encountered this with a UK company.